Unlock the Potential of

manufacturing precision

Access Reliable

AM Solutionsfor Every Need

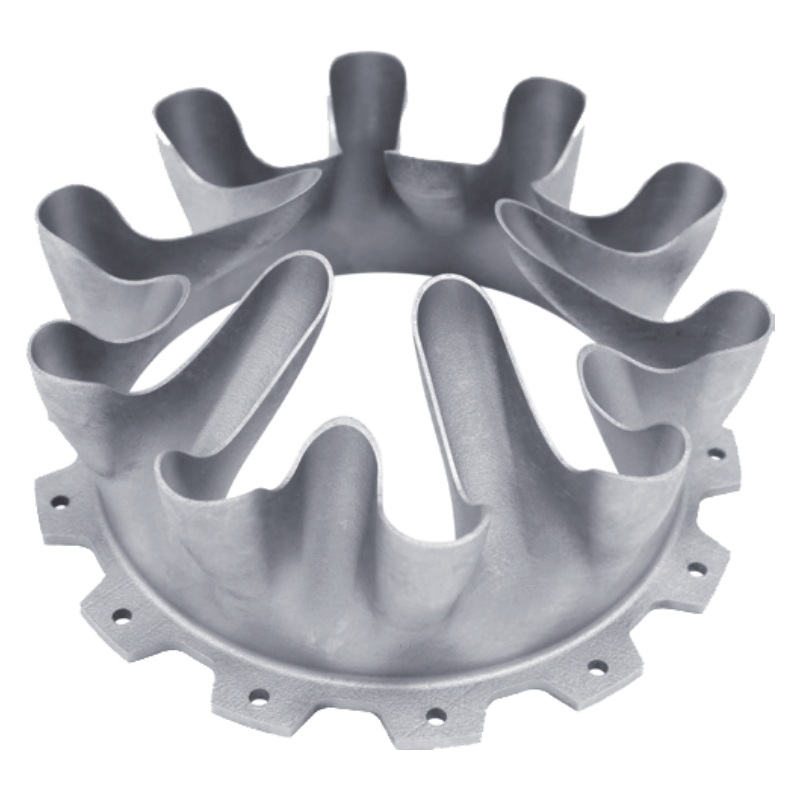

Discover Innovative

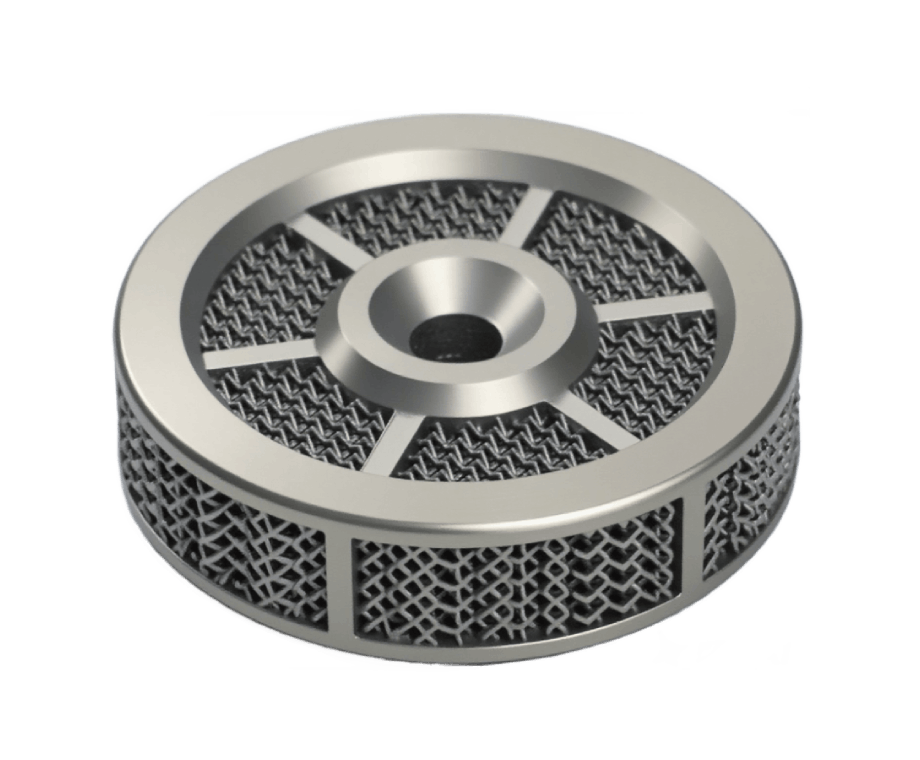

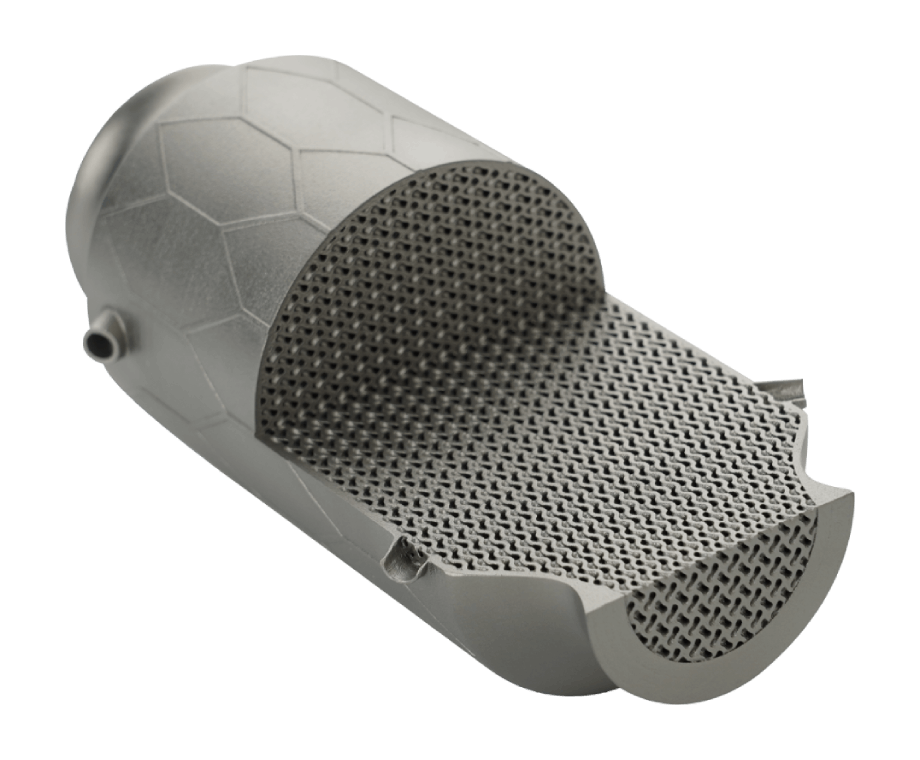

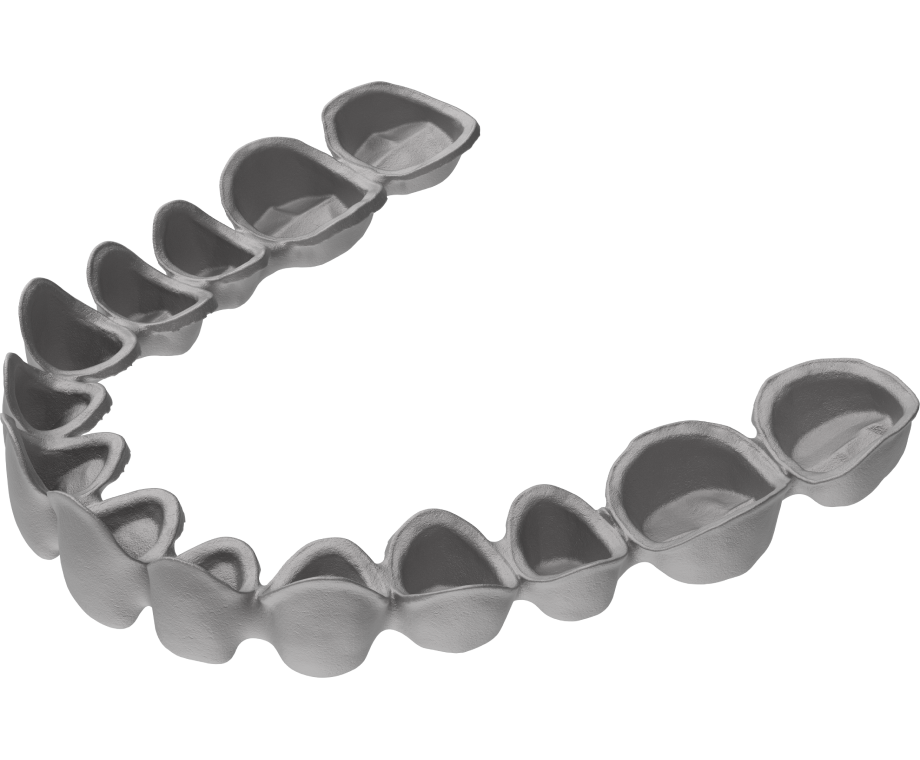

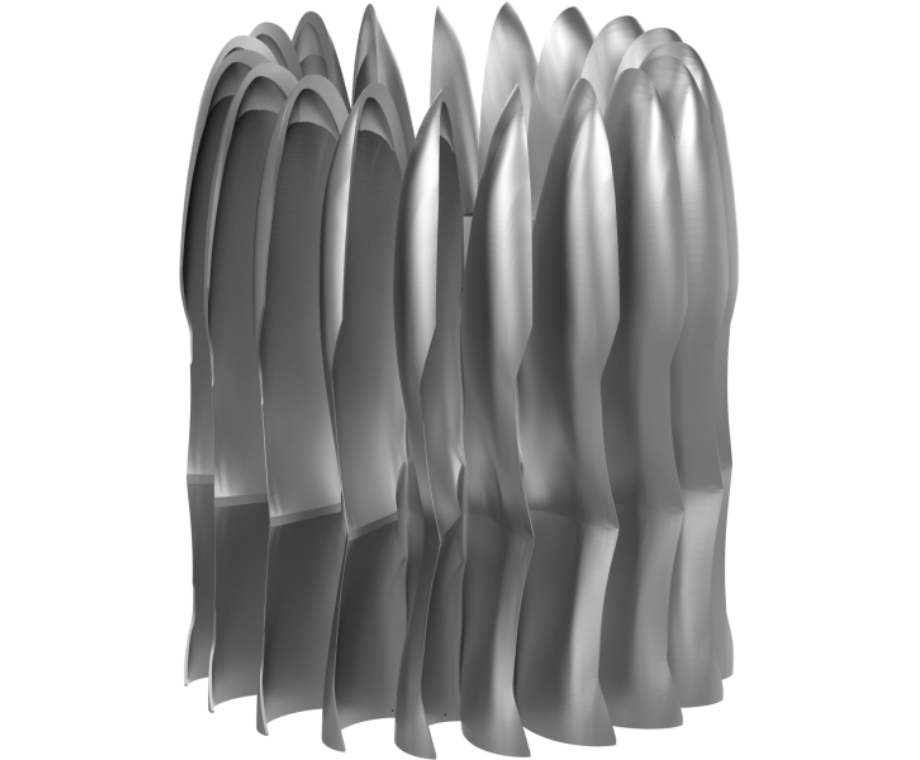

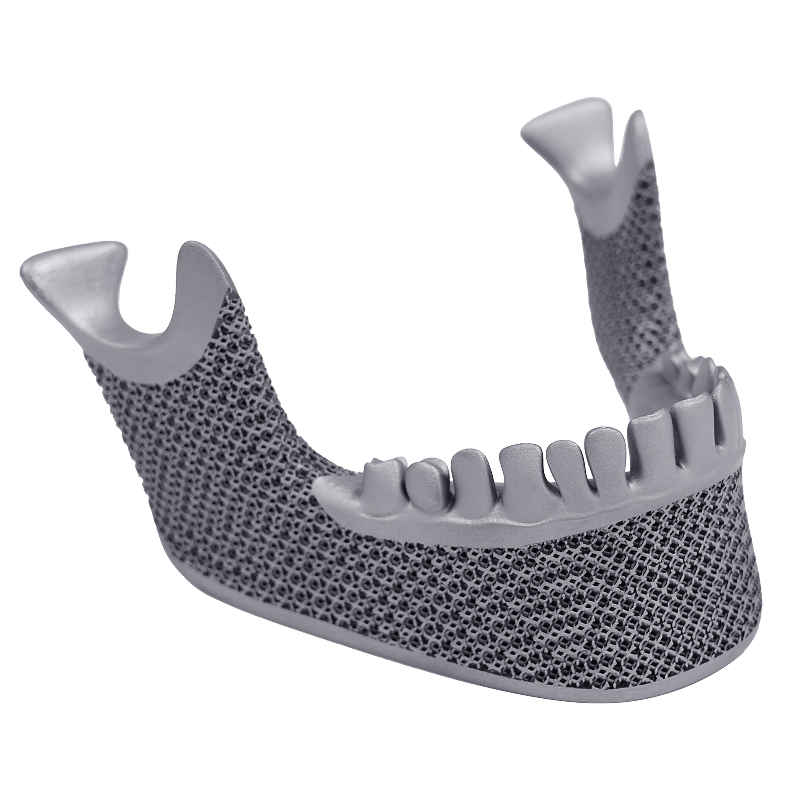

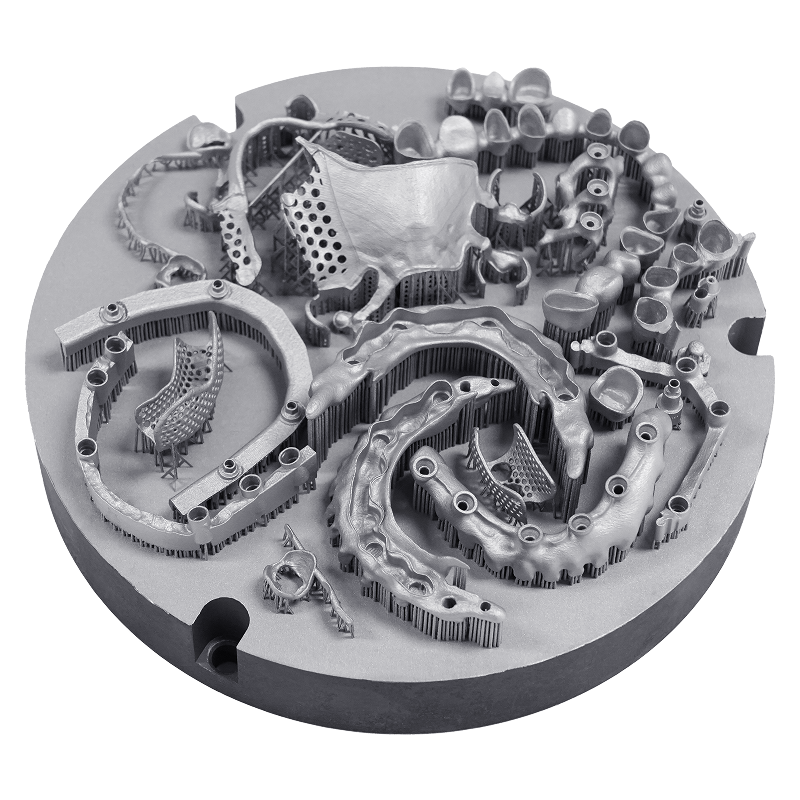

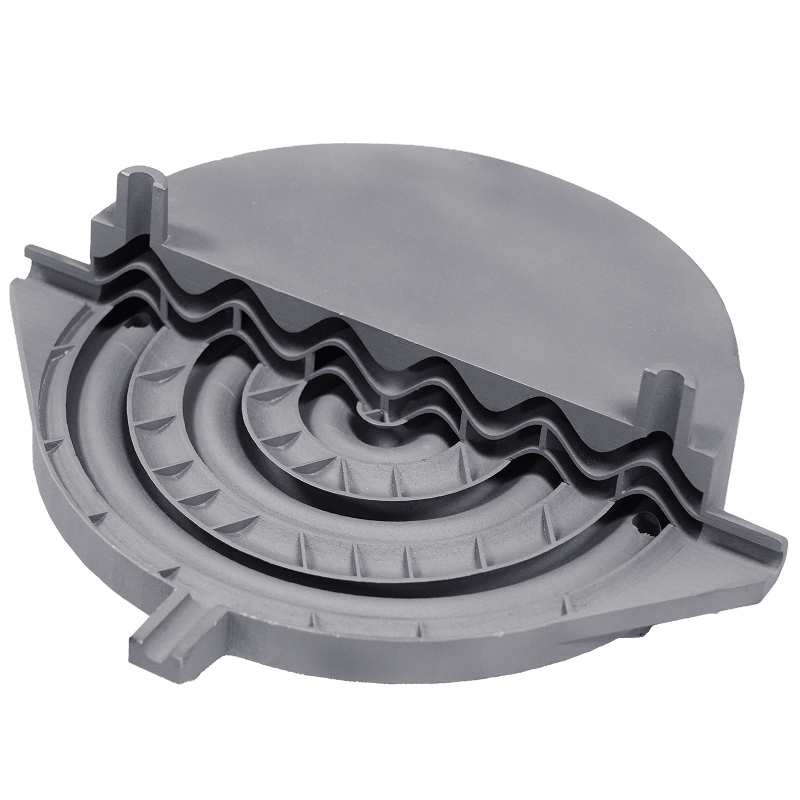

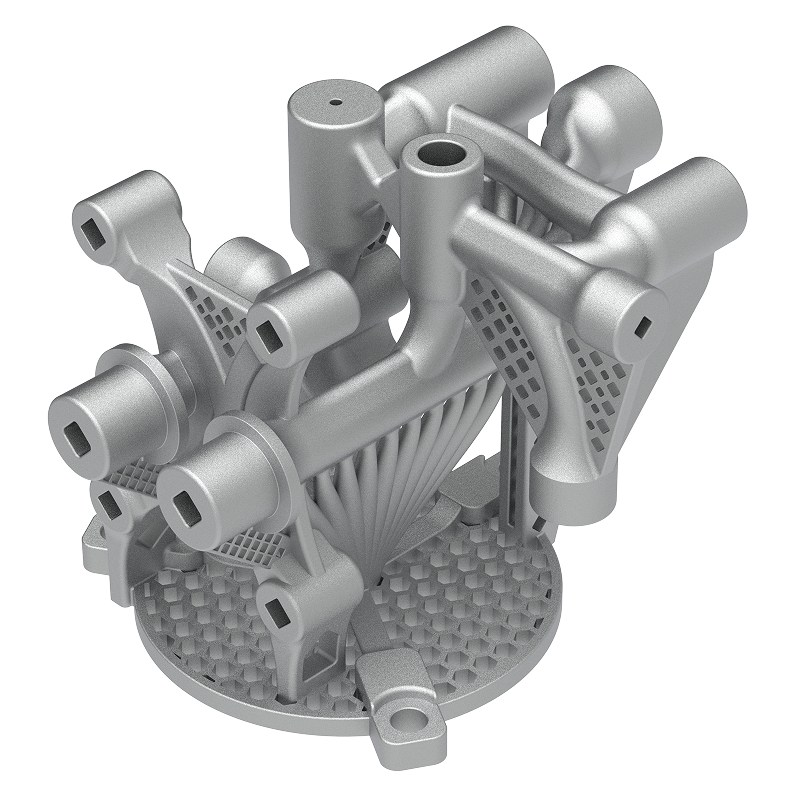

Metal 3D PrintingApplications

Partners and Clients

Partners and Clients

IndustryHighlights

Oct 29, 2025

Sep 03, 2025

Jul 04, 2025

Oct 29, 2025

Sep 03, 2025

Jul 04, 2025

View More

Event Calendar

FORMNEXT ASIA

August 26-28

Manufacturing

Shenzhen, China

FABEX 2025

October 12 - 15, 2025

Industrial

Riyadh, Saudi Arabia

FORMNEXT FRANKFURT

November 18 - 21, 2025

Manufacturing

Frankfurt, Germany