HBD recently hosted the “HBD Metal 3D Printing Footwear Mold Manufacturing Seminar” in Ho Chi Minh City, attracting over 50 industry leaders and experts to explore groundbreaking advancements in metal 3D printing for footwear mold manufacturing.

HBD Metal 3D Printing Footwear Mold Manufacturing Seminar in Vietnam

HBD’s commitment to footwear mold innovation is reinforced by strategic partnerships with industry leaders like Huali Industrial Group, enabling HBD to continuously develop and refine its technology to meet the evolving needs of footwear manufacturers.

HBD Signed a Strategic Cooperation Agreement with HuaLi industrial Group

During the seminar, the HBD team showcased their innovative metal 3D printing solutions specifically designed for the footwear mold sector. The event also featured insights from HBD’s strategic partners, who shared valuable experiences and perspectives on industry advancements.

Event Opening Speech by Rodgers Ma, Vice President of HBD

Presentation on HBD 3D-printed Shoe Mold Applications by Vison Qiu,

Senior Regional Sales Manager at HBD

Presentation on HBD 3D Printing Shoe Mold Process by Celine Xie,

Business Development & Marketing Manager at HBD

Presentation on Optical 3D Scanner Technology Accelerating the Tooling Industry by Hoang Duc Trung, AlE

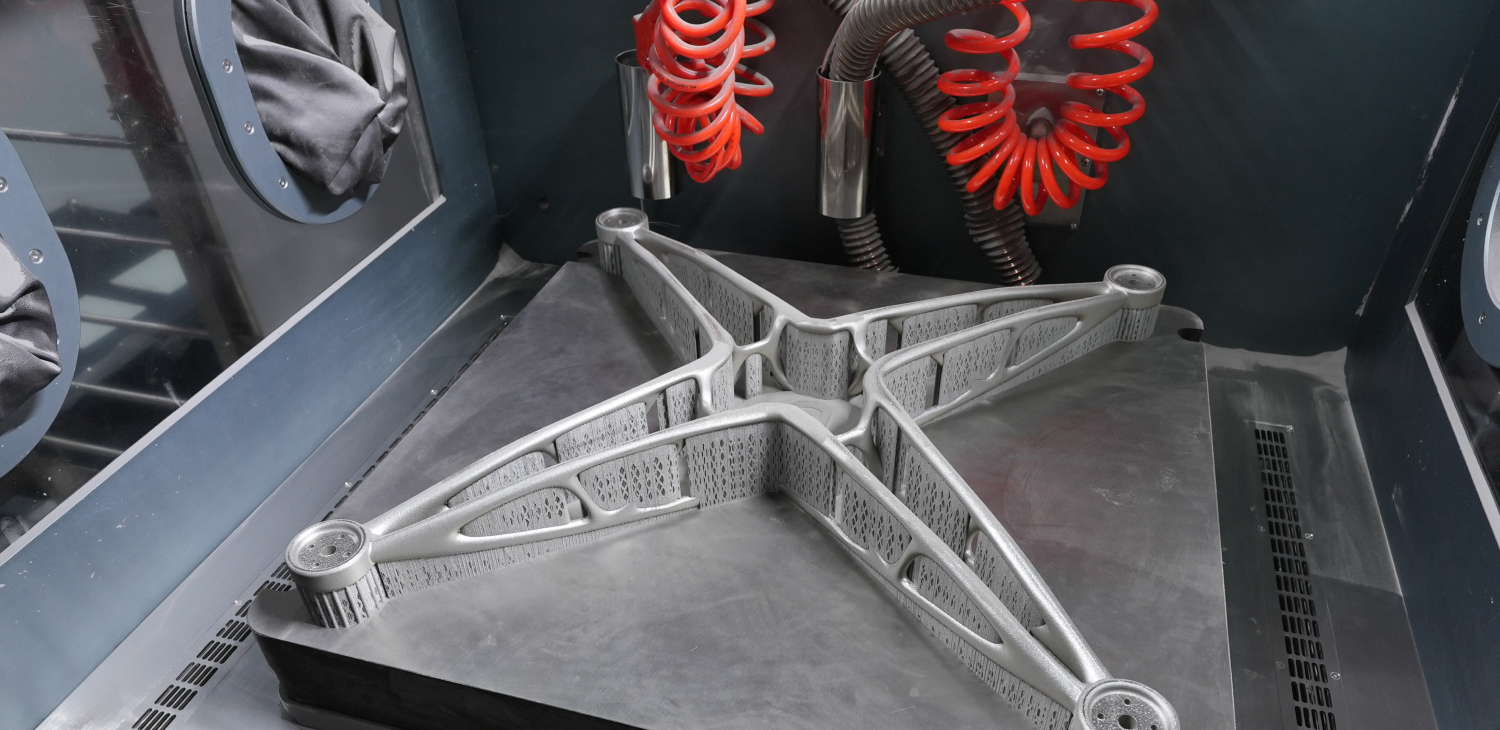

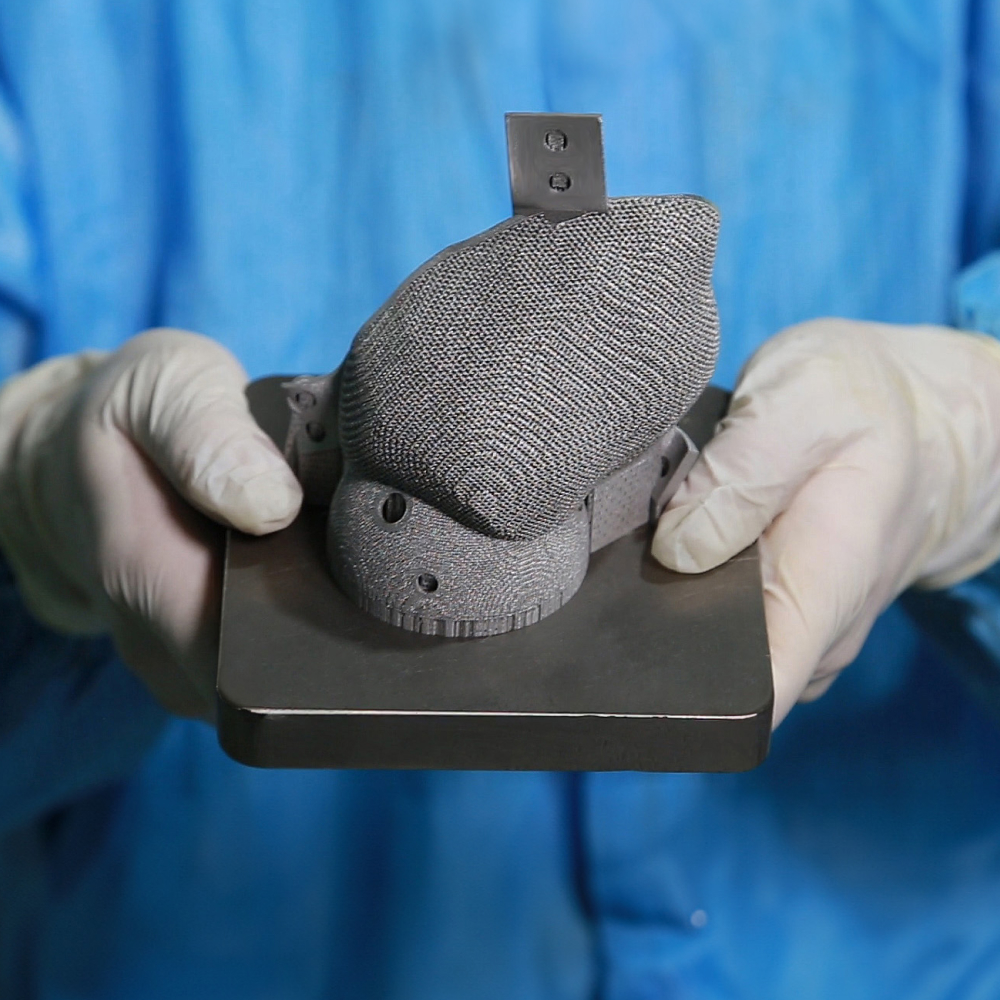

In a display that captivated attendees, HBD presented over 50 exemplary footwear mold applications, demonstrating the unique advantages of HBD’s technology. Attendees gained insight into specialized techniques for creating intricate mold features, such as the Perforated Popcorn EVA Shoe Mold, which incorporates micro-holes as small as 0.2mm seamlessly across large surfaces, showcasing the high precision achievable with HBD’s technology. The Integrated Flow Channels EVA Mold offers a significant improvement in midsole production efficiency, achieving time reductions of 40-60%. Additionally, the Air-Venting Shoe Mold features customizable pore sizes ranging from 0.03 to 0.08mm, with a density of approximately 93.5%, effectively enhancing mold performance through optimized airflow. These application cases provided a compelling demonstration of how HBD metal 3D printing can optimize mold design and improve operational efficiency in footwear production.

HBD 3D Printed Shoe Molds Showcase

A highlight of the seminar was the introduction of the HBD 400 6-Laser Metal AM System, specifically engineered for high-speed, large-scale production of footwear molds. With a build volume of 400mm x 350mm x 400mm, the HBD 400 addresses approximately 80% of standard mold size requirements. Its six-laser configuration significantly boosts printing speed and throughput, while HBD’s automatic laser stitching technology enhances process automation. The automated stitching workflow cuts calibration time from up to an hour to under 5 minutes, delivering substantial efficiency gains. With precision stitching accuracy maintained within 0.05mm, thanks to advanced algorithms and high-precision hardware, the HBD 400 achieves superior alignment and consistency across complex geometries. Equipped with HBD’s proprietary decal system, the HBD 400 also enables one-click application of detailed, three-dimensional textures without the need for post-processing, streamlining the entire production process from design to final product. Further strengthening the HBD 400’s capabilities is the HBD AMES X 3D Printing Production Intelligent Management System. The AMES X system features an intuitive interface that requires minimal training, simplifying complex tasks, optimizing layout configurations, and enhancing real-time process monitoring across production lines, making the HBD 400 an ideal solution for companies transitioning to smart manufacturing and embracing Industry 4.0.

Presentation on Advancing Mass Production of 3D-printed Shoe Molds by Dr. Pu Deng,

Material & Process Development Manager at HBD

As metal 3D printing gains traction within the footwear industry, HBD is dedicated to providing cutting-edge solutions that empower traditional mold manufacturers to transition toward intelligent, sustainable production. This seminar represents a significant step forward in HBD’s mission to lead the evolution of footwear mold manufacturing through metal additive technology.

Group Photo of HBD Footwear Mold Seminar in Vietnam