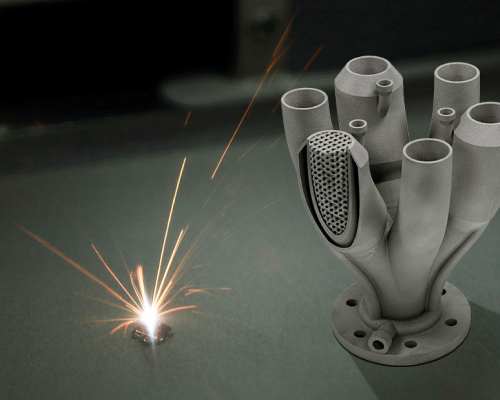

Mold Steel CX Powder is making significant strides across diverse industries, with a primary focus on applications such as injection molds and tool manufacturing. In injection molds, its superior corrosion resistance and dimensional stability make it a preferred choice, ensuring precision in the production of high-quality molded parts. In tool manufacturing, Mold Steel CX is gaining popularity for its age-hardened stainless steel composition, guaranteeing longevity and reliability in various tooling applications, from cutting tools to forming dies.

Mold Steel CX is a precipitation-hardened stainless steel that sets itself apart from other mold steels with its exceptional corrosion resistance. This inherent trait ensures the longevity and reliability of components manufactured using Mold Steel CX Powder, making it the optimal material for applications exposed to corrosive environments.

Moreover, Mold Steel CX achieves a hardness range of 45 to 50HRC through heat treatment, and it maintains outstanding dimensional stability even after this process. This dual capability holds significant relevance in high-precision injection mold manufacturing applications where hardness is critical for performance and durability.

Mechanical Properties

| Direction | Material State | Yield

Strength Rp0.2/Mpa |

Tensile Strength Rm/Mpa | Elongation

after Break A/% |

Hardness |

| Level | Printing State | 900±100 | 1000±100 | (16±3)% | 35±3 HRC |

| Heat Treatment State | 1500±100 | 1600±100 | (10±2)% | 48±2 HRC |

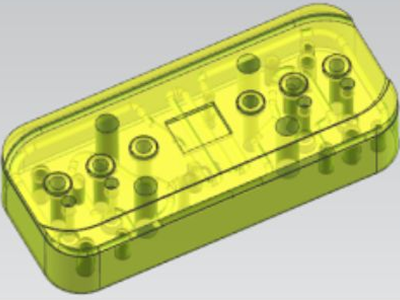

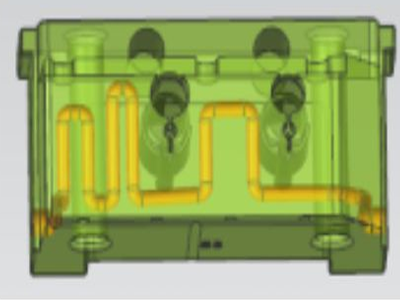

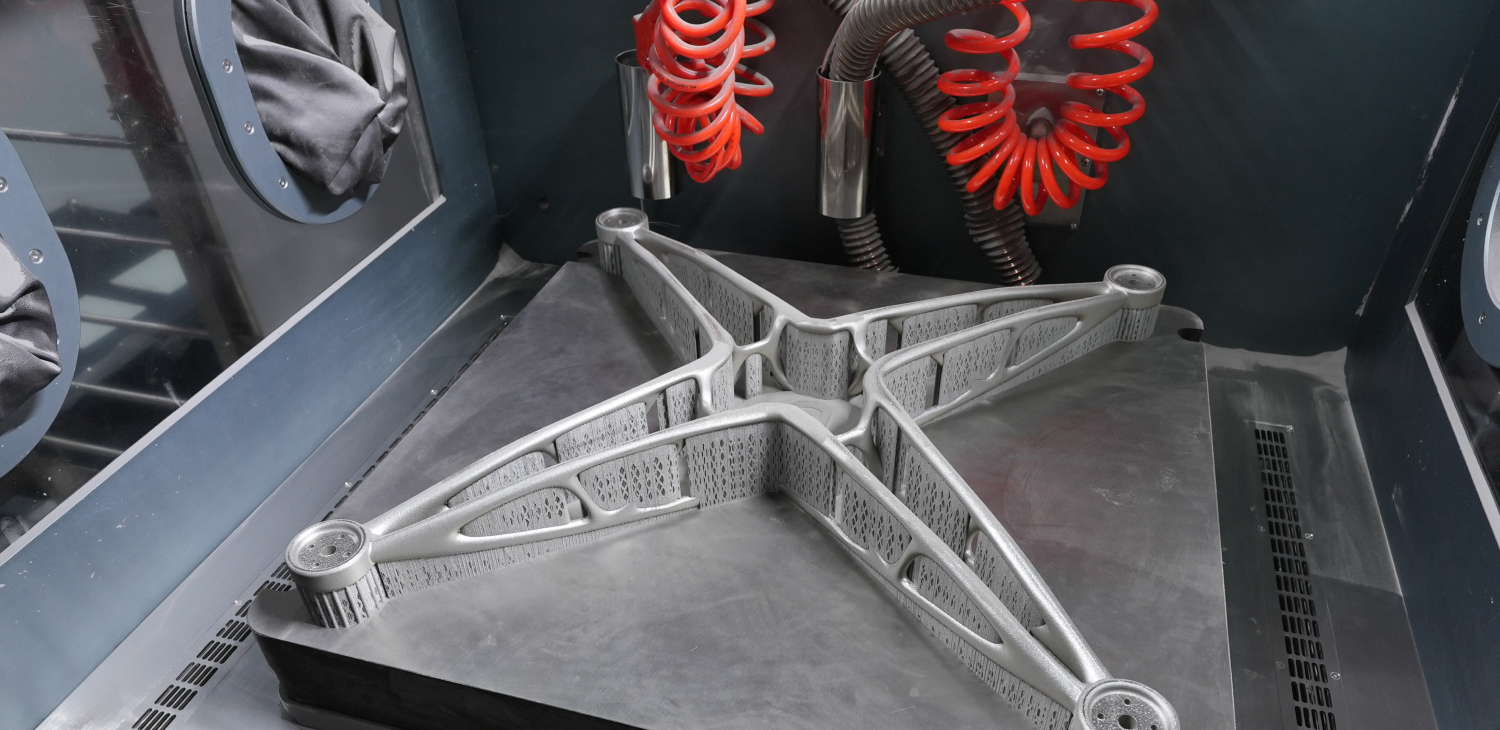

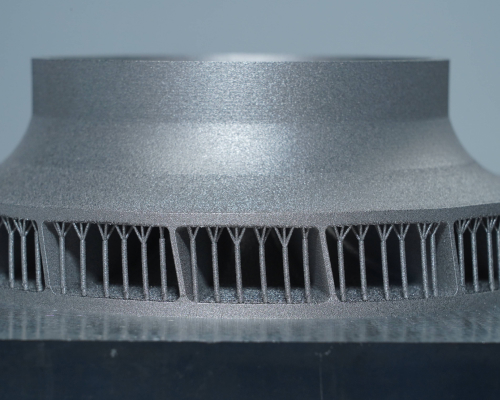

In our recent application case involving the injection molding of foot basin mold inserts, we focused on optimizing the high-temperature manufacturing conditions for this set of inserts and minimizing deformation in the injection-molded products through the design of conformal cooling mold channels. We utilized Corrax and 18NI300 mold steel powder as the primary printing materials for this set of molds, employing both the HBD 350 and HBD E500 printing devices to complete the production of the foot basin mold.

Control Lower Cover Rear Mold Insert

Heating Bracket Row Position

Upon applying this mold set in production testing, our client observed a significant reduction in the average injection molding cycle, resulting in a notable 31% increase in production efficiency. With substantial cost savings and improved product quality, our client ultimately integrated this set of conformal cooling mold inserts into the large-scale production line.

If you’re looking to explore more possibilities of metal 3D printing technology, reach out to HBD today. Let’s engage in a discussion on how we can collaborate to elevate your additive manufacturing projects.