Milling tools are vital in modern manufacturing and play a critical role in enabling high-value sectors such as aerospace, automotive, and precision mold-making. Their performance directly impacts machining efficiency, workpiece precision, and production costs—making them a key driver in the industry’s evolution toward intelligent and high-efficiency manufacturing.

As demands for higher machining precision and productivity continue to rise, the limitations of traditional milling tools—marked by a dual constraint of performance and efficiency—are becoming increasingly evident:

Excessive weight and poor adaptability: Solid structures lead to high tool weight, making it difficult for small-scale machine tools to accommodate large-sized cutters, thus limiting machining capacity.

Insufficient vibration resistance: Conventional casting methods cannot optimize internal structures, making tools susceptible to vibrations that degrade surface finish and shorten tool life.

Low manufacturing efficiency: Traditional subtractive processes require multiple steps including forging, machining, and assembly, resulting in significant material waste and extended production cycles.

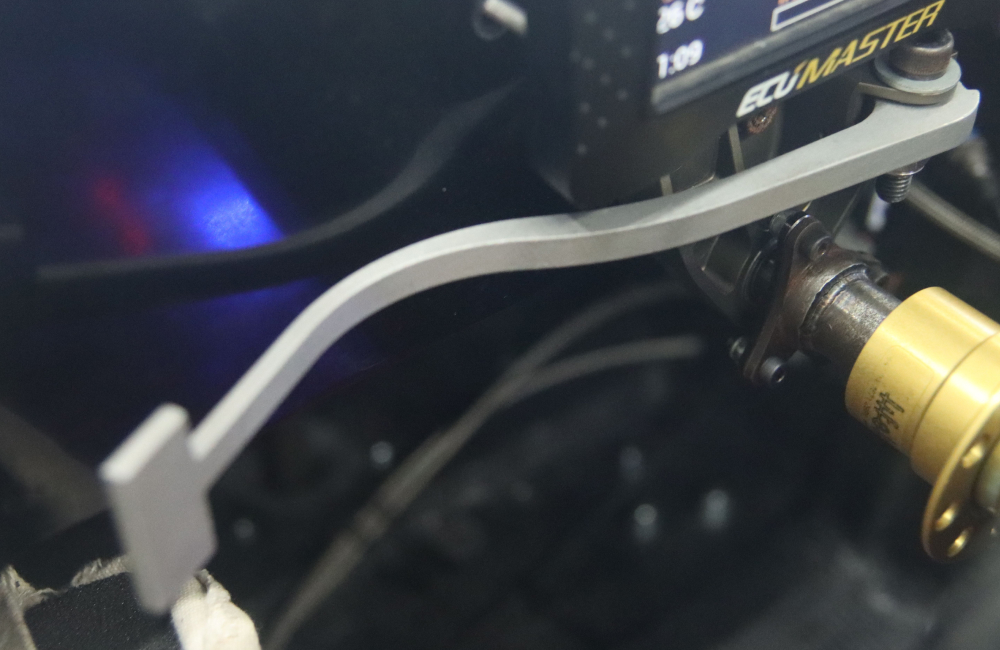

At TCT Asia 2025, HBD presented a groundbreaking milling cutter head (see Figure 1), highlighting the transformative power of metal additive manufacturing in cutting tool innovation.

This cutter head features an internally optimized bionic honeycomb lattice structure, designed through topology optimization. The lattice core not only significantly reduces the tool’s weight—by more than 60%—but also enhances vibration resistance, directly addressing two of the most persistent limitations of traditional solid tools: excessive mass and poor dynamic performance. Thanks to this lightweight internal geometry, even compact machine tools can support larger milling heads, dramatically improving cutting efficiency and overall machine utilization. Furthermore, the reduced tool weight lowers the load on the spindle, helping to extend spindle life during high-speed machining.

Beyond structural innovation, this tool showcases the benefits of integrated additive forming. Traditional manufacturing of similar tools involves multiple stages such as forging, machining, and welding, often taking weeks to complete. In contrast, HBD’s metal 3D printing enables a “design-to-part” one-step process, significantly shortening lead times. In addition, unused metal powder can be recycled, reducing material waste and lowering production costs.

This real-world application exemplifies how HBD is redefining the performance boundaries of cutting tools by merging bionic design and advanced manufacturing, paving the way for the next generation of intelligent, efficient, and sustainable production solutions.

Figure 1 (Milling cutter head with bionic honeycomb lattice structure)

HBD 400: The Core Engine Driving Industrial Implementation

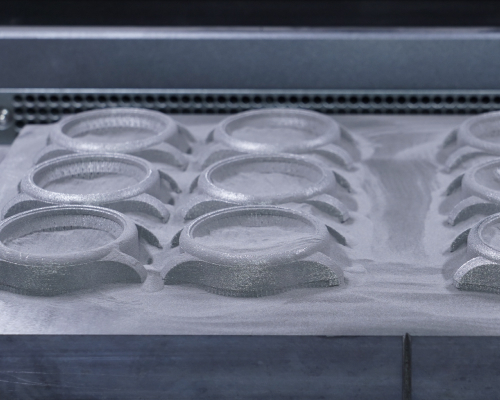

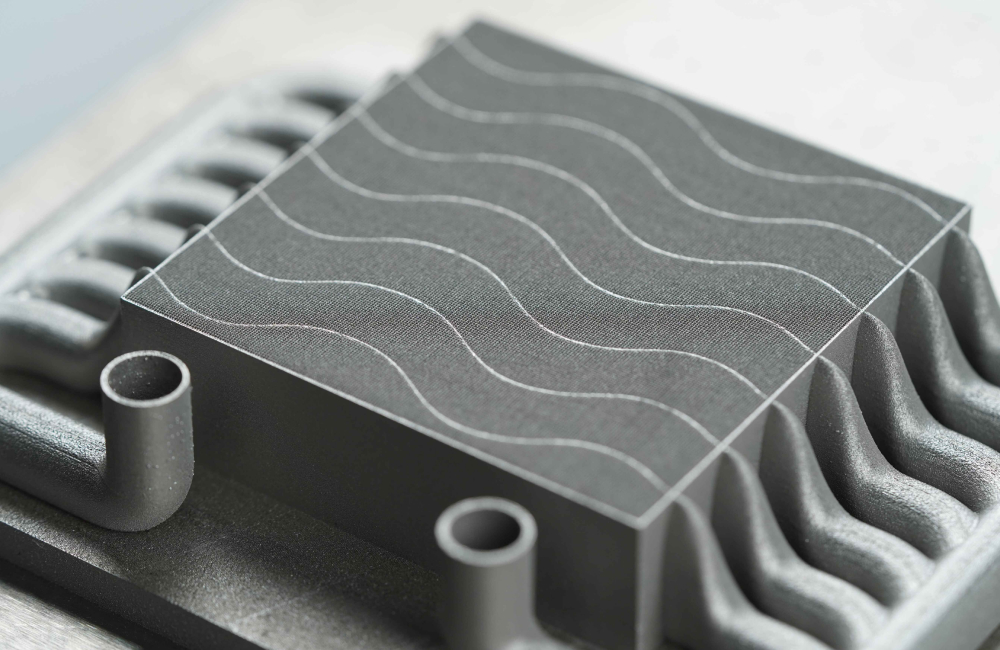

The HBD 400 metal 3D printer (see Figure 2), with a 350 × 400 × 400 mm build volume and 8×500W laser setup (see Video 1), is built for high-efficiency batch production of milling tools. Powered by the Guangchi II tech, it delivers up to 12.8× faster printing speeds than dual-laser systems—ideal for the high-volume demands of CNC consumables.

Optimized energy control reduces overheating, ensuring dense, precise parts with minimal stress—crucial for cutter heads requiring strength and vibration resistance. Multi-laser stitching enables seamless printing of large-diameter tools, while the 8-laser parallel mode allows multiple high-precision tools to be printed in one job, cutting production time.

With bi-directional powder recoating for added stability and quality, the HBD 400 combines speed, accuracy, and scalability—delivering a powerful solution for modern tooling applications.

Figure 2 (HBD 400 metal 3D printer)

Video 1 (8×500W laser)

By fusing cutting-edge design with industrial-grade additive manufacturing, HBD is pushing the boundaries of tool performance and production efficiency. As we continue to explore the full potential of metal 3D printing in sectors like aerospace, automotive, and precision manufacturing, we look forward to partnering with global innovators to accelerate the adoption of next-generation tooling solutions—driving a smarter, more sustainable future for advanced manufacturing.

You can find more information on our website at https://en.hb3dp.com or contact us via email at info@hb3dp.com.