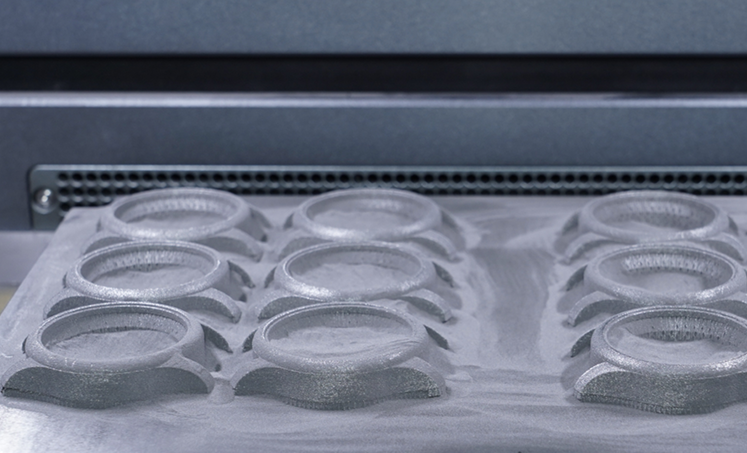

Entry-level metal 3D printers designed for precision and small-scale production. Ideal for prototyping and small-batch runs, these systems deliver reliable, high-quality parts in a compact size.

HBD 200/200D

Request Offer

Structure & Features

1

2

3

4

1Integrated Data Processing System

HBD data processing software enables the seamless creation of customizable print layouts with automated support structure integration, intelligent slicing, path scanning planning, and error rectification.

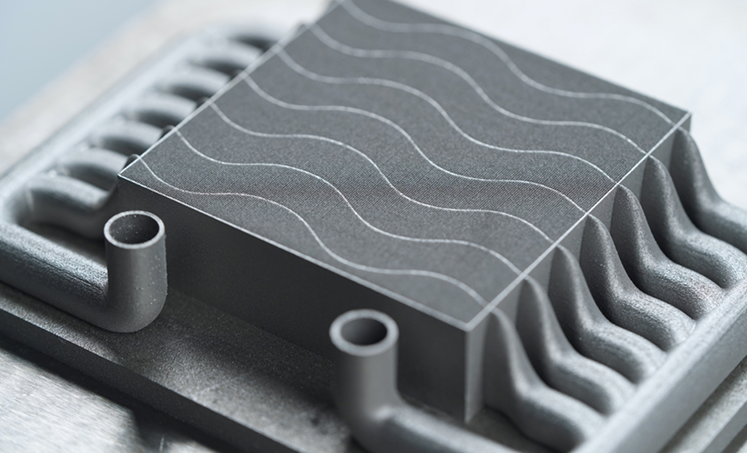

2Intelligent Powder Spreading Module

HBD 200 employs a high-strength structure to guarantee even and reliable powder distribution. This module optimizes layer consistency, crucial for achieving complex geometries and fine surface finishes.

3External Purification System Meeting H13 Standards

Equipped with an external purification system that connects in real-time to the host machine, ensuring high filtration efficiency meeting H13 standards, and featuring a filter lifespan of over 1200 hours for uninterrupted printing operations.

4Dual Lasers Configuration

Configuring two fiber lasers with a power output of up to 500W each to operate stably within a space of 270mm×170mm×120mm, maximizing production efficiency for small batches.

Get the Full Specs of the

HBD 200/200D

Want to dive deeper into the capabilities of the HBD 200/200D?

Download our product brochure to explore its full specifications, applications, and more.

PDF Download

Want to dive deeper into the capabilities of the HBD 200/200D?

Download our product brochure to explore its full specifications, applications, and more.

PDF Download

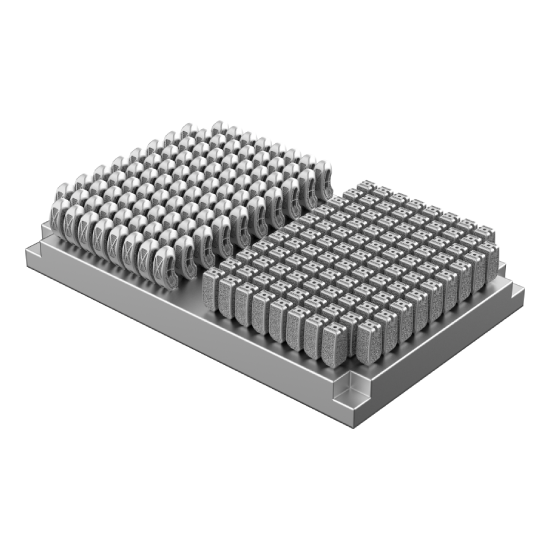

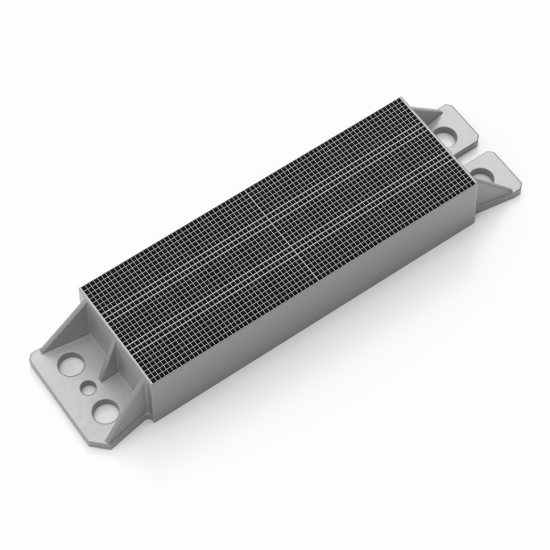

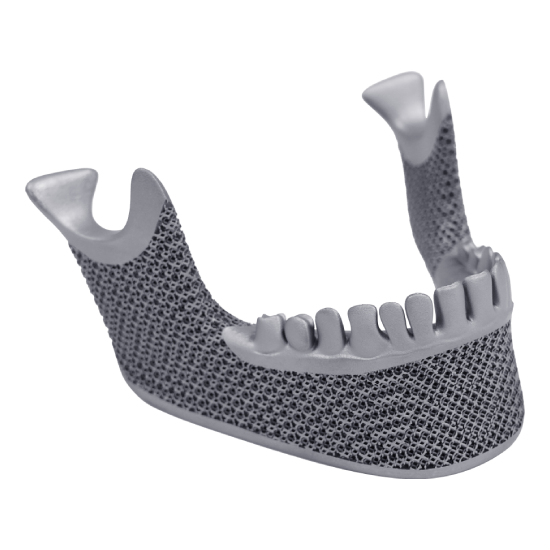

Print Case Studies

Industry Application

HBD S200: Redefining Precision in Metal 3D PrintingLearn More

We are excited to introduce the HBD S200 Metal AM System, meticulously optimized and engineered to meet high manufacturing accuracy standards.With an optimized optical system, the HBD S200 achieves a laser spot diameter of 30μm and layer thicknesses down to 10μm, enabling high resolution of detail…

HBD's Innovative Titanium Smartwatch Case: 3D Printing Revolutionizes Design and Manufacturin.Learn More

The smartwatch case printed by HBD 200 Metal AM System, crafted from titanium alloy Ti-6Al-4V, with a wall thickness ranging from 1.5 to 2.5mm, measures 51x42x10mm and weighs a mere 16 grams. Compared with traditional manufacturing technologies, its weight is reduced by 48%…

Video Collection

Enhance Your Workflow with

Our Auxiliary Equipment

HBD 200/200D

Technical Specifcations

Build Volume:

265mm x 170mm x 120mm(height incl. build plate)

Laser Power:

2 Lasers, 300w/500W

Layer Thickness:

10μm-50μm

Scanning Track Width:

40μm-80μm

Scanning Speed:

≤10m/s

Oxygen Content:

≤100ppm

Protective Atmosphere:

Integral sealed, automatic monitoring of oxygen content, recycling cleaning and collection coefficient ≥ 99%

Relative Density:

99.9%+

Typical Accuracy:

0.05-0.1mm

Metal Powder:

Titanium alloy, cobalt-chromium alloy, stainless steel, mold steel, etc.

Process Parameter Configuration:

Tailored parameter set for the specific application, user-modifiable

weight:

Est. 1150kg

Extornal Dimonsions:

1780mmx1380mmx 1900mm

Power Suppiy:

300W:AC220V, 50/60Hz peak power ≤4.5kW, average power ≤3kW

500W:AC380V,50/60Hz, peak power ≤6kW, average power ≤4kW

500W:AC380V,50/60Hz, peak power ≤6kW, average power ≤4kW

Ready to Transform Your Production? Let’s Talk!

Our team is here to help you with pricing, customization options, and more. Contact us today for a tailored quote.