Flexible mid-sized metal 3D printers featuring multi-laser configurations to meet diverse industry needs. These systems are optimized for complex parts and increased build rates, accommodating a wide range of metal powders.

HBD 350

Request Offer

Structure & Features

1

2

3

4

5

6

1Control System

The HBD 350 is equipped with a robust control system, offering comprehensive system logs for in-depth performance tracking. Its high-efficiency software is designed for swift data processing, ensuring precise control throughout the printing process.

2Intelligent Powder Spreading Module

Featuring a single or dual-direction, variable-speed powder spreading system, the HBD 350 employs a high-strength structure to guarantee even and reliable powder distribution. This module optimizes layer consistency, crucial for achieving complex geometries and fine surface finishes.

3Powder Collection Module

The dual powder collection canister design, minimizes the frequency of powder changes. This setup enhances productivity by reducing downtime during powder recycling and storage.

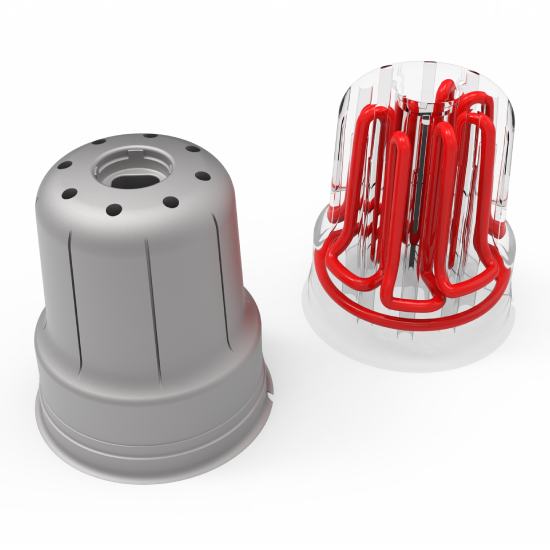

4Recirculation and Purification System

The system includes automatic oxygen removal, reverse blowing, and humidification functions. Its independently sealed filter can be safely removed and replaced, reducing the risks associated with handling fine metal powders. This closed-loop system maintains an optimal printing atmosphere, ensuring consistent part quality.

5Precision Optics and Multi-Laser System

Designed with a fully sealed optical path and precise water-cooled temperature control, the multi-laser system of the HBD 350 offers high accuracy and stability. The fixed-focus optical structure enables consistent energy distribution, essential for producing high-resolution parts with complex details.

6Automated Powder Feeding System

The automated powder supply system continuously monitors powder levels in the storage hopper, enabling uninterrupted powder replenishment. This ensures a smooth, efficient printing process, particularly useful for large builds or mass production runs.

Get the Full Specs of the

HBD 350

Want to dive deeper into the capabilities of the HBD 350?

Download our product brochure to explore its full specifications, applications, and more.

PDF Download

Want to dive deeper into the capabilities of the HBD 350?

Download our product brochure to explore its full specifications, applications, and more.

PDF Download

Print Case Studies

Industry Application

Powering Precision: HBD Metal 3D Printing Fuels Tongji TJURacing's Charge at Formula SAE Japan 2024Learn More

As the 2024 season of global Formula Student Automotive Engineering (FSAE) competitions begins, university racing teams worldwide are preparing for one of the year’s most anticipated events—the Formula SAE Japan 2024 competition,This year’s competition features 80 official teams…

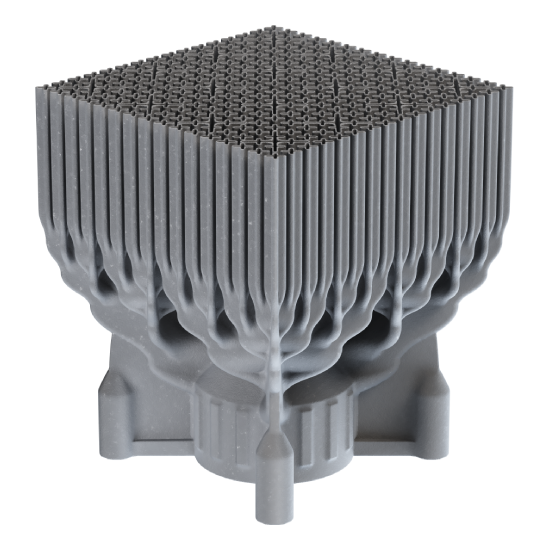

From 45° to 6°: HBD's Turbine Blade Printing Milestone with 96% Support ReductionLearn More

Metal 3D printing technology has always been one of the most notable areas in manufacturing. However, the presence of support structures has long been one of the significant factors limiting the application scope of this technology,The addition of appropriate support structures ensures the stability of printed parts …

Video Collection

Enhance Your Workflow with

Our Auxiliary Equipment

HBD 350

Technical Specifcations

Build Volume:

325mm x 325mm x 400mm(height incl. build plate)

Laser Power:

2 Lasers, 500w/1000W

4 Lasers,500w/1000W

4 Lasers,500w/1000W

Layer Thickness:

20μm-120μm

Scanning Track Width:

70μm-200μm

Scanning Speed:

≤10m/s

Oxygen Content:

≤100ppm

Protective Atmosphere:

Integral sealed, automatic monitoring of oxygen content, recycling cleaning and collection coefficient ≥ 99%

Relative Density:

99.9%+

Typical Accuracy:

0.05-0.2mm

Metal Powder:

Titarium allkoy, aluminiumn alloy, high terperature alloy, stainless steel, rnoid stoel, etc.

Process Parameter Configuration:

Tailored parareter set for the specifikc application, user-medifiable

weight:

Est. 3000kg

Extornal Dimonsions:

1900mmx1500mmx 2300mm

Power Suppiy:

500W: AC380v,50/60Hz, peak power sl4-15kw, average power ≤5.5-7kW

1000W: AC380V,50/60Hz, peak power sl5-17kW, average power ≤7-9kW

1000W: AC380V,50/60Hz, peak power sl5-17kW, average power ≤7-9kW

Ready to Transform Your Production? Let’s Talk!

Our team is here to help you with pricing, customization options, and more. Contact us today for a tailored quote.