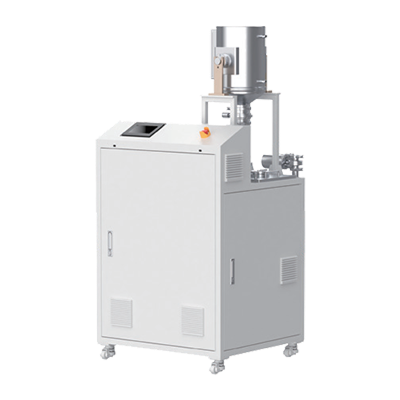

A mid-sized metal 3D printer with a compact 6-laser setup, engineered to maximize production efficiency within a fixed build volume. Perfect for high-volume batch manufacturing, it combines productivity with precision.

HBD 400

Request Offer

Structure & Features

1

2

3

4

5

6

1Automatic Laser Stitching System

One-click multi-laser alignment with automatic stitching verification.

The automated stitching workflow reduces calibration time from up to an hour to under

5 minutes, delivering notable efficiency gains. Utilizing advanced algorithms and

high-precision hardware, the stitching accuracy is maintained within 0.05mm.

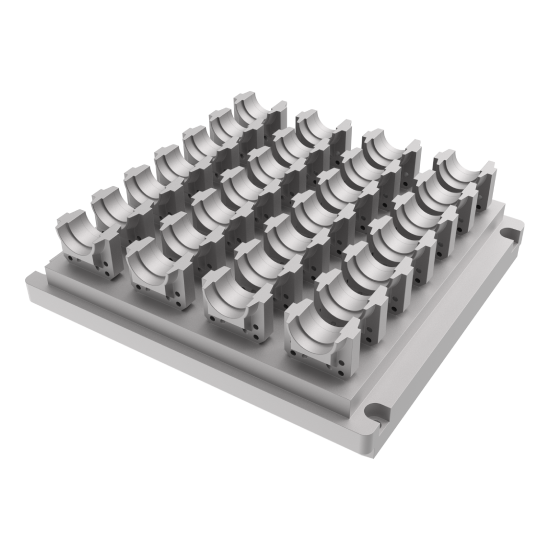

2Intelligent Powder Spreading Module

Intelligent variable speed design and bidirectional re-coater completing the recoating

process in 3 seconds, the HBD 400 employs a high-strength structure to guarantee even

and reliable powder distribution. This module optimizes layer consistency, crucial for

achieving complex geometries and fine surface finishes.

3Powder Collection Module

The dual powder collection canister design, minimizes the frequency of powder changes.

This setup enhances productivity by reducing downtime during powder recycling and

storage.

4Long-lasting Filtration System

The filtration system utilizes next-generation PTFE-coated filter elements, meeting H13

standards with a capture efficiency of up to 99.9%, capable of trapping particles as small

as 0.3μm. The filter includes self-cleaning features, providing a filter element lifetime of

over 5 years. Optimized gas-flow configuration enables secure and efficient waste

reclamation in inert gas environments, ensuring optimal printing conditions.

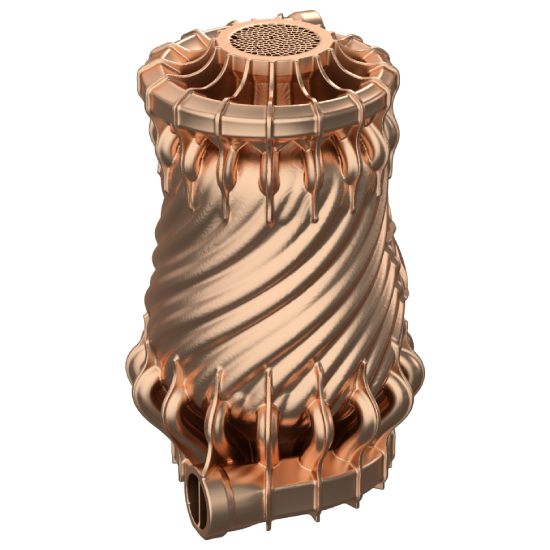

5Precision 6-Laser System

Six precise 500W/1000W fibre lasers operate, coupled with a building volume of

350mm×400mm×400mm, this results in an efficient solution for serial production.

6Automated Powder Feeding System

The automated powder supply system continuously monitors powder levels in the storage

hopper, enabling uninterrupted powder replenishment. This ensures a smooth, efficient

printing process, particularly useful for large builds or mass production runs.

Get the Full Specs of the

HBD 400

Want to dive deeper into the capabilities of the HBD 400?

Download our product brochure to explore its full specifications, applications, and more.

PDF Download

Want to dive deeper into the capabilities of the HBD 400?

Download our product brochure to explore its full specifications, applications, and more.

PDF Download

Print Case Studies

Industry Application

CN PRECISION TECHNOLOGY & HBD: Integrated Full-Process Solution Enhances Value in Precision ManufacturingLearn More

Metal additive manufacturing offers significant advantages in design freedom and production agility. However, when it comes to precision components such as high-end watches, which require impeccable surface quality, mirror-like finishes, and strict tolerances, traditional approaches often face challenges in post-processing…

HBD Reinvents Milling Performance with Metal 3D PrintingLearn More

Milling tools are vital in modern manufacturing and play a critical role in enabling high-value sectors such as aerospace, automotive, and precision mold-making. Their performance directly impacts machining efficiency, workpiece precision, and production costs—making them a key driver in the industry’s evolution toward intelligent and high-efficiency manufacturing…

Video Collection

Enhance Your Workflow with

Our Auxiliary Equipment

HBD 400

Technical Specifcations

Build Volume:

325mm x 400mm x 400mm(height incl. build plate)

Laser Power:

4 Lasers, 500w/1000W

6 Lasers,500w/1000W

6 Lasers,500w/1000W

Layer Thickness:

20μm-120μm

Scanning Track Width:

70μm-200μm

Scanning Speed:

≤10m/s

Oxygen Content:

≤100ppm

Protective Atmosphere:

Integral sealed, automatic monitoring of oxygen content, recycling cleaning and collection coefficient ≥ 99%

Relative Density:

99.9%+

Typical Accuracy:

0.05-0.2mm

Metal Powder:

Titanium Alloys, Aluminum Alloys, Superalloys, Stainless Steel, Mould Steel, Etc.

Process Parameter Configuration:

Tailored Parameter Set For The Specific Application, User-Modifiable

weight:

Est. 3300kg

Extornal Dimonsions:

1900mmx1650mmx 2300mm

Power Suppiy:

500W: AC380v,50/60Hz, peak power sl4-16kw, average power ≤5.5-8.5kW

1000W: AC380V,50/60Hz, peak power sl5-19kW, average power ≤6.5-11.5kW

1000W: AC380V,50/60Hz, peak power sl5-19kW, average power ≤6.5-11.5kW

Ready to Transform Your Production? Let’s Talk!

Our team is here to help you with pricing, customization options, and more. Contact us today for a tailored quote.