Precision, Efficiency, and Sustainability for Modern Molding Solutions

Precision, Efficiency, and Sustainability for Modern Molding Solutions

Explore EnablementWhy It's Better

HBD Metal 3D printing transforms molding by enabling faster, more efficient production with innovative features like conformal cooling channels. These optimized internal cooling paths significantly reduce cycle times and enhance product quality, while improving durability and lowering costs.

Cost-efficiency

Durable and Reliable

Enhanced Efficiency

How 3D Printing

is Making a Difference

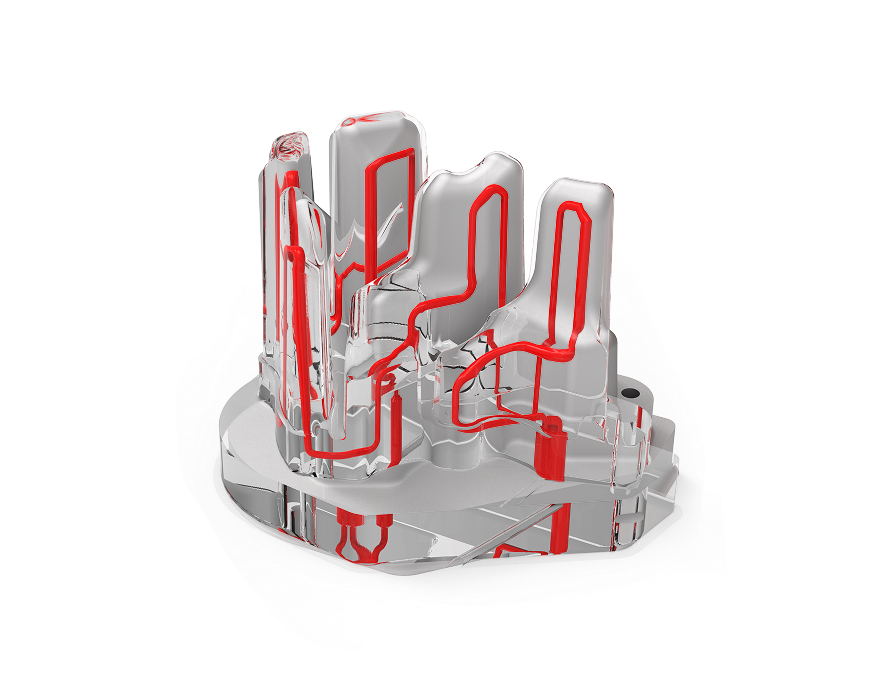

Conformal Cooling for Enhanced Heat Dissipation

- Advantage: 3D printing enables the design of conformal cooling channels that follow the mold geometry, improving heat dissipation efficiency.

- Problem Solved: Reduces cycle times, minimizes thermal stress, and improves product consistency by achieving uniform cooling across complex mold surfaces.

- Typical Application: Conformal Cooling Injection Mold

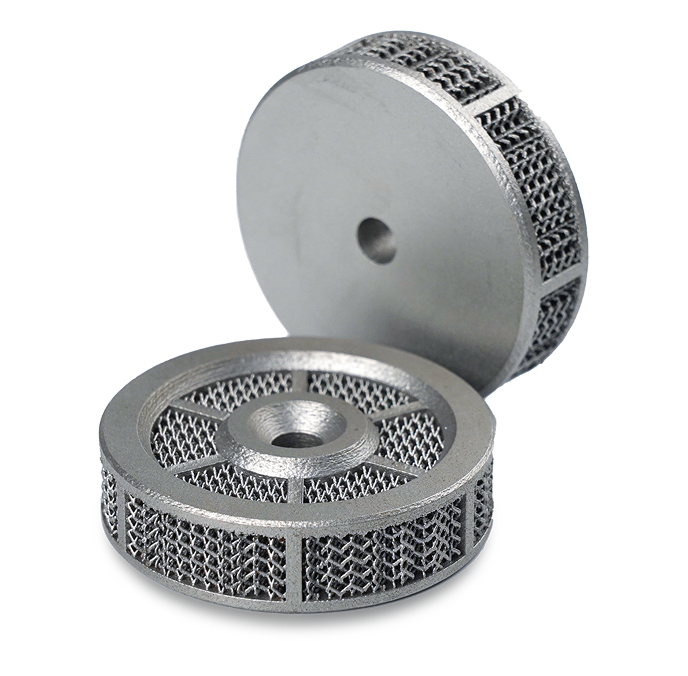

High-Efficiency Batch Production for Precision Mold Components

- Advantage: LPBF technology enables rapid and precise batch manufacturing of intricate mold inserts and components.

- Problem Solved: Reduces lead times and machining costs for high-precision small mold components, improving overall production efficiency.

- Typical Application: Hot Runner Inserts

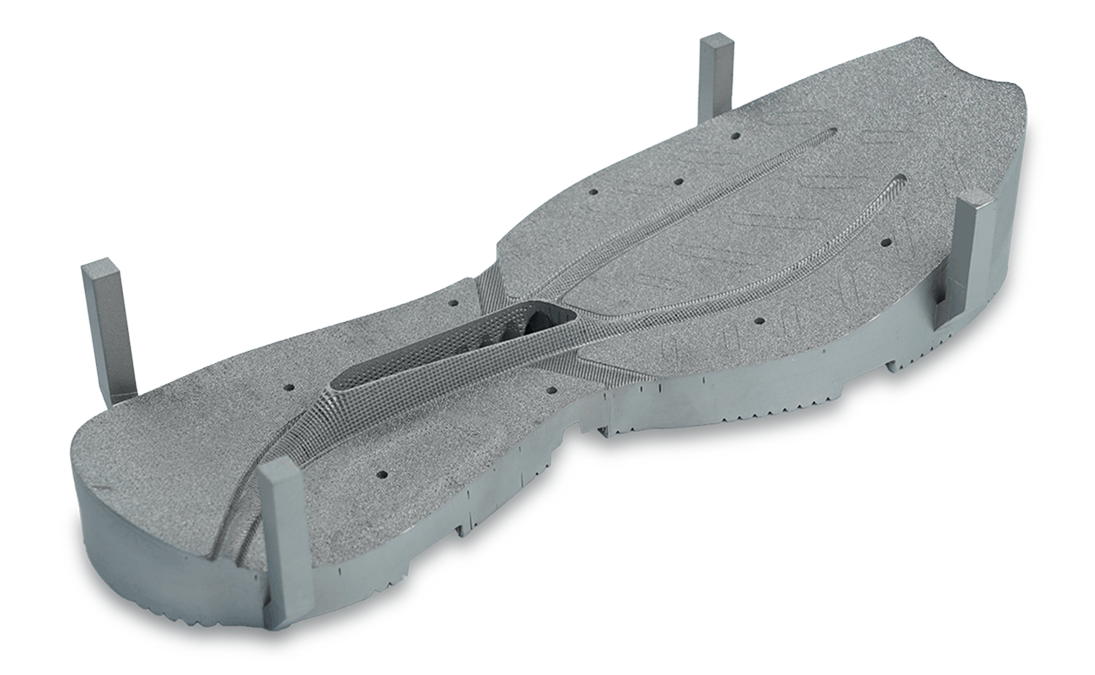

Microporous Structures for Ventilation & Defect Reduction

- Advantage: Producing metal molds with integrated micropores improves air permeability to improve gas evacuation and prevent molding defects.

- Problem Solved: Eliminates issues like trapped air, burns, and surface defects in molded parts, enhancing mold performance and product quality.

- Typical Application: Air-Venting Shoe Mold

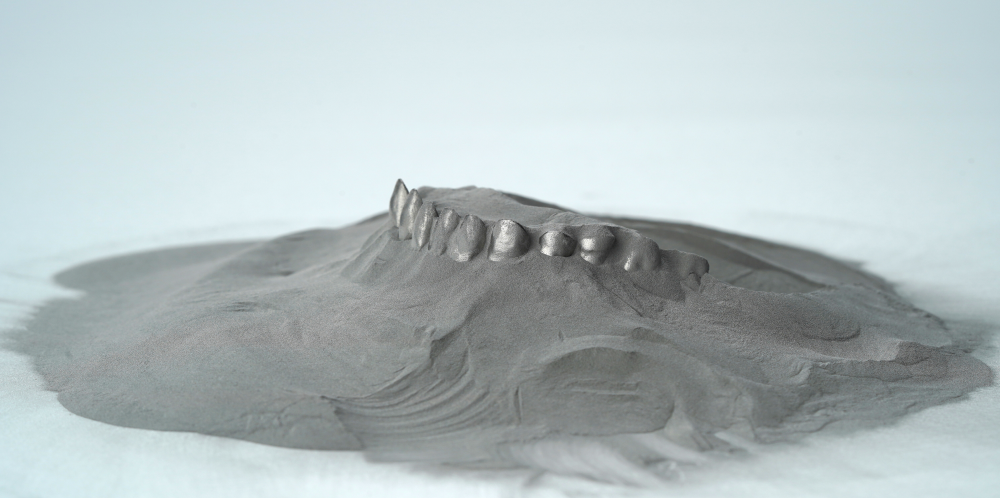

High-Resolution Surface Texturing for Complex Patterns

- Advantage: Direct printing of intricate textures onto mold surfaces eliminates the need for secondary etching or machining.

- Problem Solved: Reduces processing steps and enables highly detailed textures with consistent quality, even for complex geometries.

- Typical Application: Aluminum Alloy Patterned Sole Mold

Recommended Models

HBD 200/200D

Build Volume

158mmx 100mm(height incl. bulld piate)

Laser Power

1 Laser, 300W 2 Lasers,300W

HBD 350

Learn more

HBD 400

Learn moreThe Right Materials for the

Perfect Dental Solution

Cobalt-Chromium Alloy

Co-Cr Alloy

Why Choose It:

Strong and resistant to corrosion—great for long-term use.

Best For:

Dental crowns and bridges.

Titanium Alloy

0Ti6AL4V

Why Choose It:

Strong and resistant to corrosion—great for long-term use.

Best For:

Dental crowns and bridges.

Trusted by

Leading Dental Professionals

Take Your Manufacturing to New Heights with HBD 3D Printing

Contact us to learn how HBD’s advanced metal 3D printing solutions can help you achieve lightweight, high-performance designs that meet the demands of aerospace. Together, we can create innovative solutions that push the limits of engineering and manufacturing.

Start Product Finder